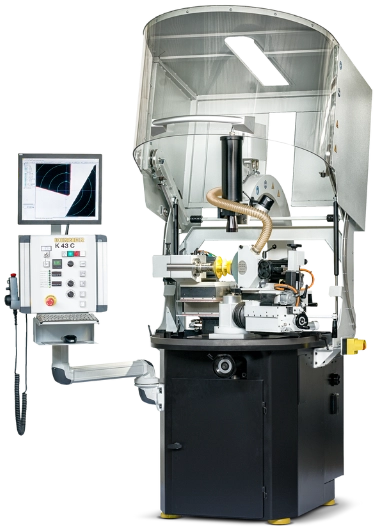

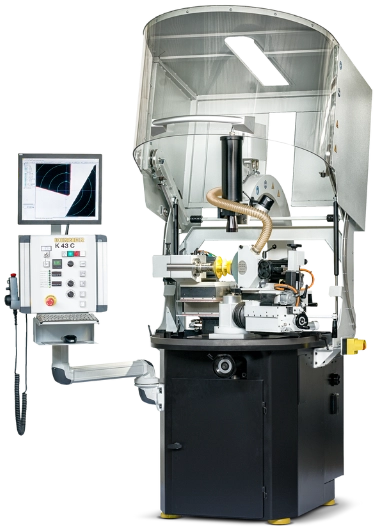

- Telecentric precision optics with up to 110 times zoom capability makes everything perfectly visible. Now also with motorized zoom upon request!

- Newly designed telecentric backlight source ensures a high-resolution reproduction

- Comfortable import of disk data in DXF-/DWG-format and overlay incl. machining options using in-house developed KirCam-Mini-CAD visualization software.

- Compact, fully integrated and network-compatible industrial PC with Windows® operating system and pivoting industrial panel, suitable for rough environmental conditions and for the comfortable parameterizing of the dressing task.

- Completely new designed oscillating actuator. Using operating hand wheel and buttons the adjustment of the oscillation position and the oscillating stroke is carried out in no time.

- Flexible machining options for the individual wheels and wheel packs. Double-sided additional swiveling allows dressing of inconveniently configured wheel packs in the same clamping operation. The interaction with newly developed oscillating axis allows a perfect and collision-free positioning of the work piece.

- Innovative extraction – without optical impairment of the vision field during dressing of grinding disks in the dry mode – allows the operator to keep an overview.

- All established spindle/flange configurations can be incorporated. Adjustments for special cases are possible.

- On request a coolant device for “wet dressing”, including splash guard sheet metal, hoses and coolant reservoirs, is available. Alternatively, it can be used for “dry dressing” with a suction device, or also for exclusive wet dressing with emulsion/ grinding oil.

- The digital display for the swivel axis (A) – or combined with cross table (X+Y) – facilitates the preadjustment of the machine and further increases the quality of the dressing result.

- Many urther options and special solutions upon request!