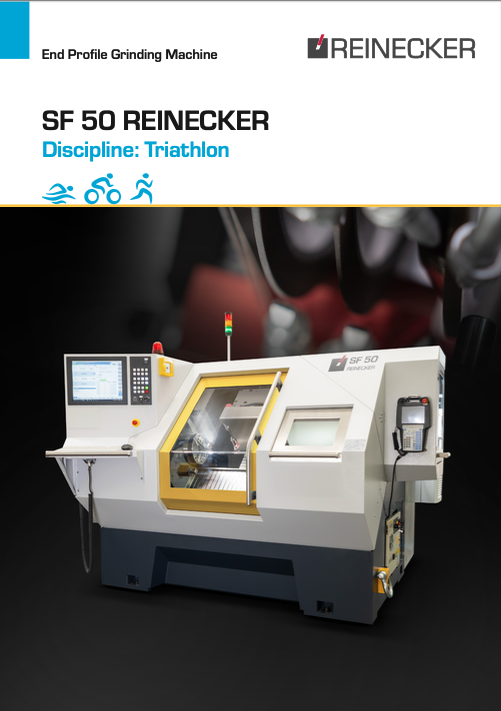

End Profile Grinding

SF 50 REINECKER

End profile grinding machine

SF 50 REINECKER

End profile grinding machine

Good to know

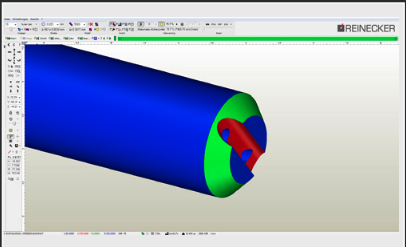

- Grinding of points, chamfers, radii, squares, tangs, whistle notches, weldon flats, and slots in any combination on tool ends of cylindrical tools made from tungsten carbide, HSS or ceramic.

- Grinding unit with a liquid-cooled motor spindle.

- Variable spindle position of the grinding unit for more flexibility, parallel or rectangular to the workpiece spindle.

- Up to four different grinding wheels can be mounted on one flange.

- Use of various chuck clamping systems.

- Measuring probe for detecting the axial workpiece position and angular position of coolant holes.

- Automatic loading devices are available as an option.

- CNC control NUM Flexium+ with powerful NUM DriveX drives and integrated safety architecture NUM-Safe.

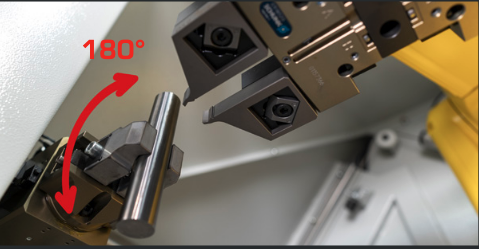

- Integrated flipping station for machining on both ends in one set up.

NUMROTOplus®

Programming system with 3D graphics